The KD500 series double column CNC vertical lathe adopts NN series bearings, and the bearing unit and spindle fixing surface are manually scraped and ground, with an accuracy of above level 0. Fully enclosed protective cover, motor, servo knife holder and other devices can be customized according to needs. The CNC system can be equipped with options such as Naco, Siemens, New Generation, Guangshu, etc.

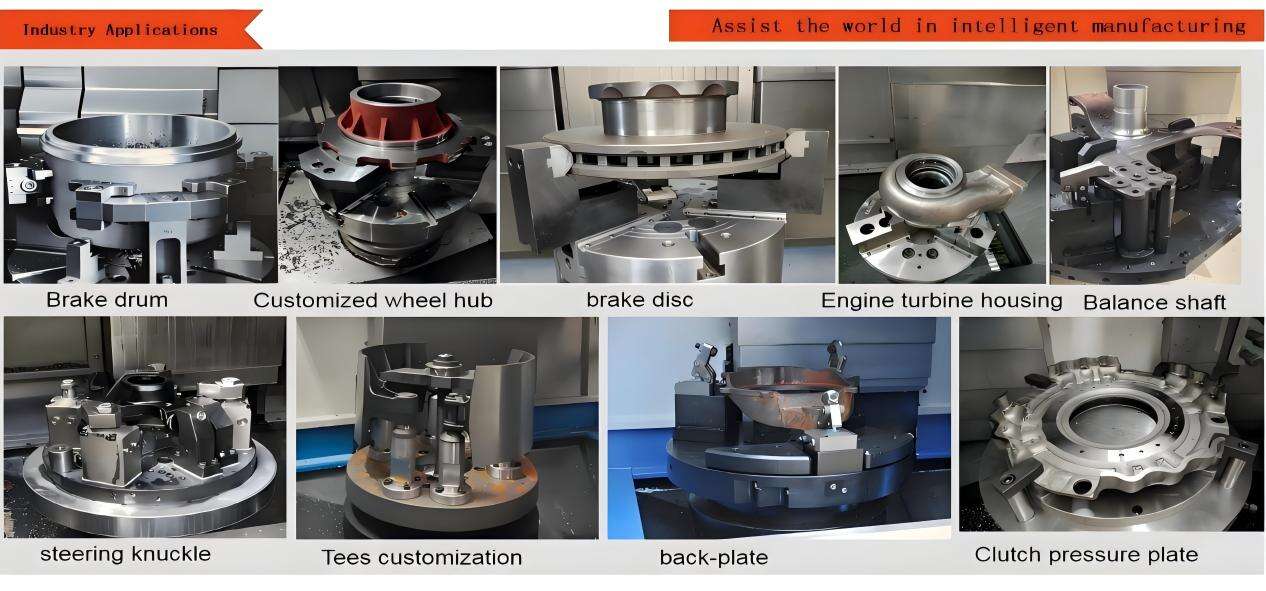

The KD500 double column machine tool is an automated CNC machining machine tool that uses a double column structure to machine the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooves, and chamfers of parts. This machine tool is particularly suitable for machining brake discs and other disc components.

KD500 double column CNC vertical lathe Support customization

Key components such as the base, column, column slide plate and slider are all made of high-grade grey cast iron (HT250). The layout of the rib plate is reasonable and each component has been tempered to ensure that the machine tool has high strength and long-term precision stability.

The machine tool adopts a double-column structure, with two sets of saddles and slides installed on the bed, which are controlled separately, effectively saving space and occupying a small area. The double column can process the rough turning and fine turning of the workpiece at the same time, effectively improving the customer's processing efficiency and reducing production costs while ensuring accuracy.

The spindle part of the machine tool is the spindle unit, which effectively guarantees the processing accuracy and roughness. The internal bearing of the spindle unit is lubricated with special grease, which is easy to install and maintain. Compared with the previous oil lubrication, the spindle unit has a lower cost, higher speed and more stable operation.

The machine tool adopts roller type linear guide rail. It has ultra-high rigidity and ultra-heavy load capacity. It greatly improves the positioning accuracy and load-bearing capacity of the machine tool's longitudinal and lateral feed motion.

The machine tool spindle pulley and the spindle CNC servo motor pulley are directly connected through a belt, and are equipped with a 30kw servo motor with stepless speed change and a wide speed range. The servo motor can meet the different requirements of the spindle speed for rough machining and finishing of parts.

The vertical and horizontal feeding are automatically controlled by the servo motor. There are protective devices in both directions.

The two ends of the ball screw in the vertical and horizontal directions of the machine tool use special bearings for the screw, and adopt a pre-stretching structure, which greatly improves and guarantees the machining accuracy of the machine tool for parts.

The machine tool uses an electric lubricating oil pump to automatically lubricate each part in an intermittent manner to ensure the lubrication of each guide pair and ball screw pair, which can extend the service life of each moving pair.

The double-column machine tool tool holder can use a double horizontal CNC tool holder, a single horizontal tool holder with a single row of tools or a double row of tools when meeting the workpiece processing requirements. The horizontal tool holder has a short tool change time and can greatly improve work efficiency.

Add Y axis according to customer requirements to meet processing needs.

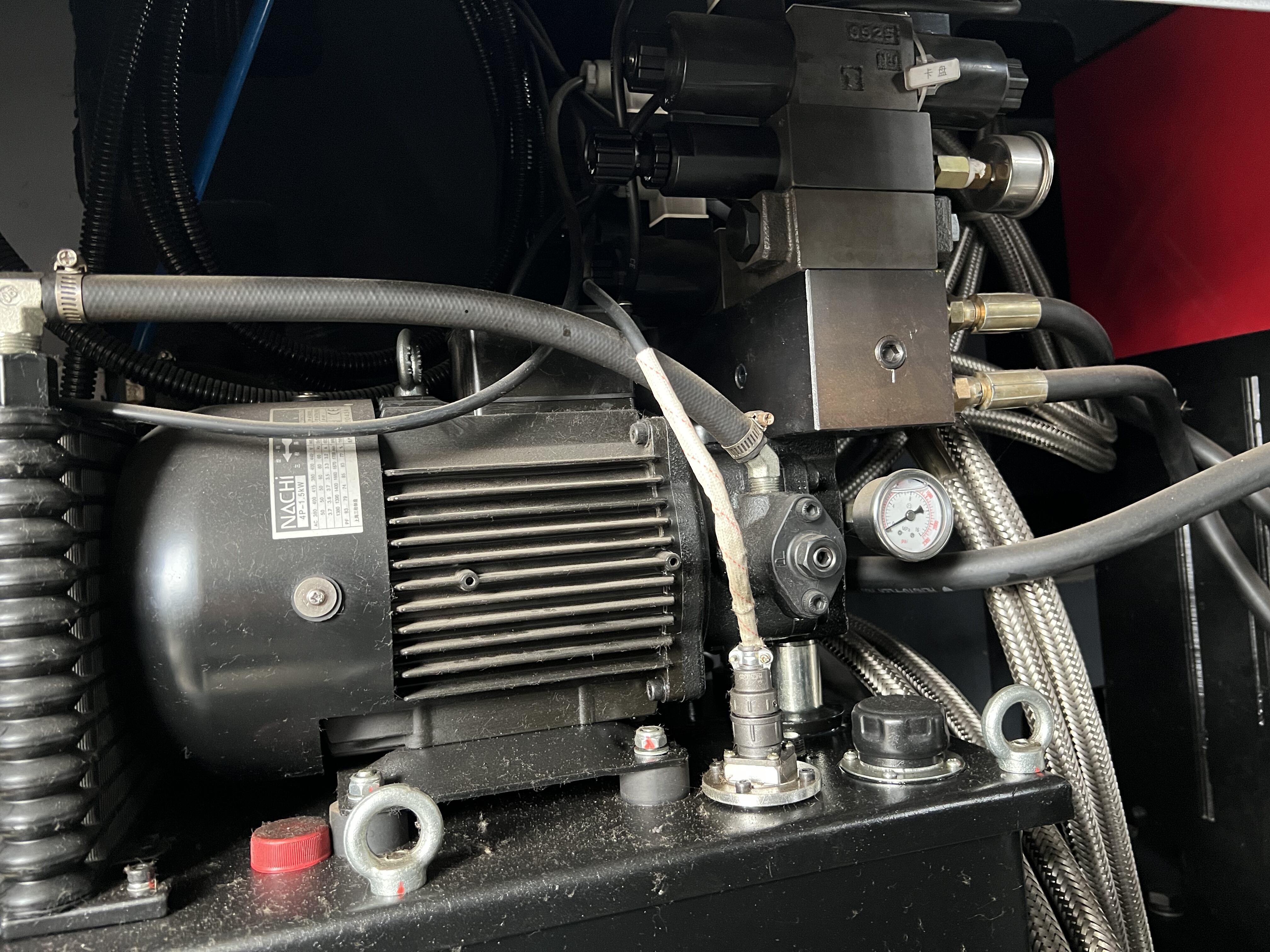

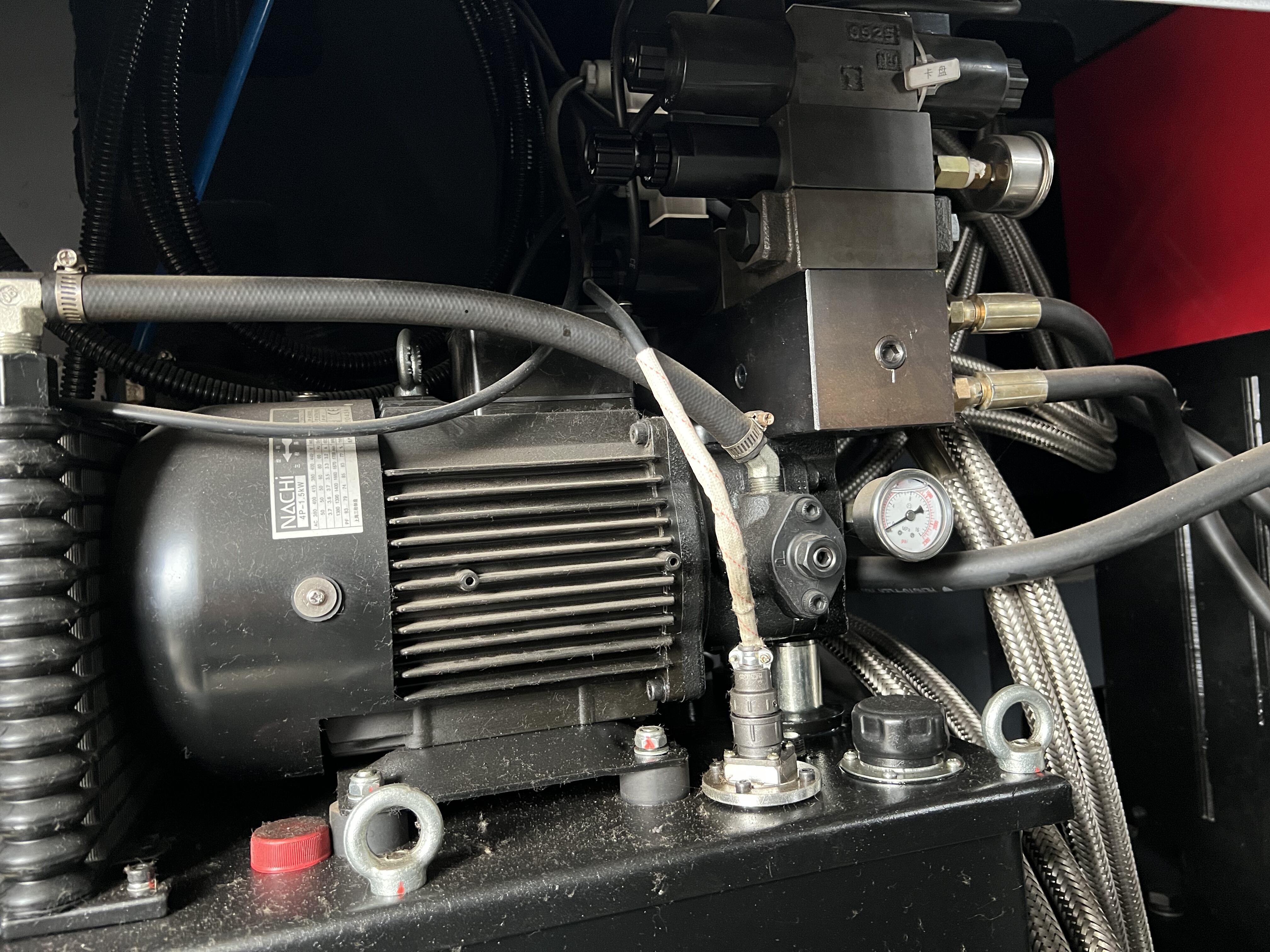

A single rotary cylinder is configured at the lower end of the spindle. The single rotary cylinder can be used to control the tooling to press the workpiece, or control the hydraulic chuck, which can reduce the labor intensity of workers and improve efficiency.

A : The conditions and period for the supplier to be responsible for quality: After the machine tool is accepted, it will enter the warranty period, which is twelve months. The equipment implements three guarantees and the warranty period is one year.

B : If the equipment fails during use, the supplier will respond within 2 hours after receiving the notice from the buyer and come up with a solution within 8 hours. If on-site processing is required, personnel will be assigned to the buyer within 48 hours to handle it.

C : If a failure occurs during the warranty period, the supplier will provide free repair services (except for damage to the machine tool caused by human factors by the buyer or the end user); the cost fee will be charged for failures caused by improper use.

D : After the machine tool arrives at the user's factory, if the installation and commissioning work cannot be carried out on time due to the buyer's reasons, the warranty period will expire 12 months after the arrival of the user, and the three guarantees service will no longer be provided.

E : Equipment accuracy standards are provided by the supplier with the contract.

| Machine parameters | |||

|---|---|---|---|

1. Device name |

CNC vertical lathe |

2. Model |

KD500 |

3. System |

Kandi K2000 |

||

Travel | |||

| x-axis | 300mm | z-axis | 500mm |

| y-axis | 60mm | ||

Capacity | |||

| Spindle speed | 100~1000rpm | Spindle motor rated power (speed/torque) | 30Kw (750 rpm, 380N.M) |

| Spindle type | A2-11 | Spindle bearings | Germany FAG/Japan NSK |

| Front bearings | NN3032K | Rear bearings | NN3026K |

| Spindle shaft hardness | HRC58-62 | Dimension-Outside | φ160mm |

Automatic tool changer | |||

| Double Work Station | Hydraulic horizontal eight-station turret | Turret Specifications | Turret center height 125mm |

| Tool Plate Specifications | 380mm standard across edge | Chuck | 18-inch hydraulic chuck |

SLIDE WAY--Taiwan | |||

| x-axis slide way | 3 pieces with 6 sliders, width 55mm | Z-axis slide way | 4 pieces with 8 sliders, width 55mm |

| Y axis (finishing turning) | 2 pieces with 4 sliders, width 30mm | ||

Ball screw (Ball screw )--Taiwan Hiwin/Intime | |||

| Ball screw accuracy | C3 level | Ball screw diameter x.y.z | x: φ50 z: φ50 y: φ25 |

| Screw bearing | Fujikoshi, Japan | ||

Control System | |||

| Standard Accessories | Kaneti K2000 | X motor (X zaxis motor) | 18NM |

| Z motor (Z zaxis motor) | 23NM | Y motor (Y zaxis motor) | 7NM |

FEED RATE | |||

X, Z, Y rapid feed rate |

20m/min |

||

Control System | |||

| Repeat positioning | 0.008mm | Positioning | 0.012mm |

| Spindle end axial runout | 0.005mm | Cutting feed speed | 0.1-1000mm/min |

| Least input increment | 0.001mm | Surface roughness | Ra1.6 |

| Machine weight | 10T | Approx. area (length × width × height) | 2800 * 2400 * 2800 |

This machine tool is suitable for high-speed steel cutting tools, hard alloy cutting tools, and various high-performance cutting tools. It can process black metal, non-ferrous metal, and some non-metallic material workpieces. It can complete rough and fine machining processes such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, cutting grooves, steps, and circular arcs on the machine tool. Suitable for processing parts with large batch sizes, high machining accuracy, and high requirements for dimensional consistency.

Customer visit

Customer visit

Yes, we support ODM/OEM, and can design and customize exclusive models according to your needs.

A: Please tell me your specifications. We can choose the best model for you. You can also send us the product drawing. We will choose the most suitable machine for you.

A: 30% down payment after the contract, 70% payment before ship.ment, can be discussed according to your situation.

A: Our factory is located in Tengzhou City,Zaozhuang. China, zip code277500.Warmly welcome you to visit us.

The delivery time is 7-10 days. If you choose a special configuration, the delivery time will be correspondingly extended