The Taiyun KD800 vertical lathe adopts a high-speed, high-precision, and high rigidity unit assembly structure, with NN series bearings for better stability. Adopting high-precision Taiwanese guide rails to ensure accuracy.

The KD800 series CNC single column vertical lathe is a high-tech electromechanical integrated product developed by our company, which has absorbed advanced design and manufacturing technology, adopted CAD optimization design methods, implemented enterprise precision standards, equipped with advanced functional components at home and abroad, achieved strong cutting in terms of structural performance, heavy-duty worktable, high dynamic and static stiffness of the machine bed, safe and reliable motion, long service life, and high processing efficiency.

VTC800 CNC Vertical Lathe

Support customization

The bed material is high-quality gray cast iron HT300 grade, which has undergone thermal aging and stress relief annealing treatment. The material is made of high-strength low stress cast iron and effective shock absorption measures are taken.

The knife holder has multiple configurations, and users can freely choose according to their actual needs and usage habits.

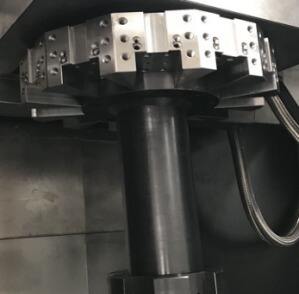

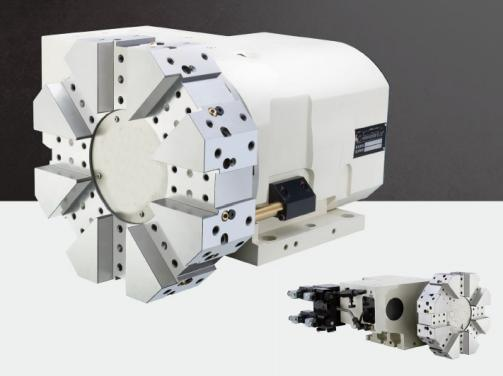

Standard configuration: Taiwan horizontal 8-station knife holder, this series of knife holders is controlled by servo motors for indexing, which can quickly select knives in both directions, with hydraulic locking and extremely high rigidity;

The Taiwan horizontal eight station servo tool holder has an excellent design structure and high rigidity. It adopts servo technology for indexing, dividing, and hydraulic locking, ensuring smooth and accurate indexing, and is particularly suitable for processing automotive industry parts.

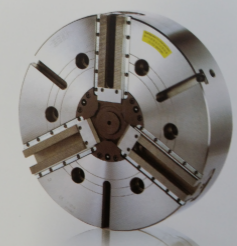

The standard chuck of this machine tool is a hydraulic chuck with a specification of 24 inches. The chuck is a waterproof chuck, and there is a sealing strip at the sliding fit between the chuck slide and the disc body, which can effectively prevent coolant from leaking to the spindle through the chuck and prevent chips from entering the sliding surface and damaging the slide.

The chuck end face has 3 T-shaped slots, making it convenient for customers to replace various fixtures and jigs. It has good adaptability and can meet the requirements of users for processing various parts.

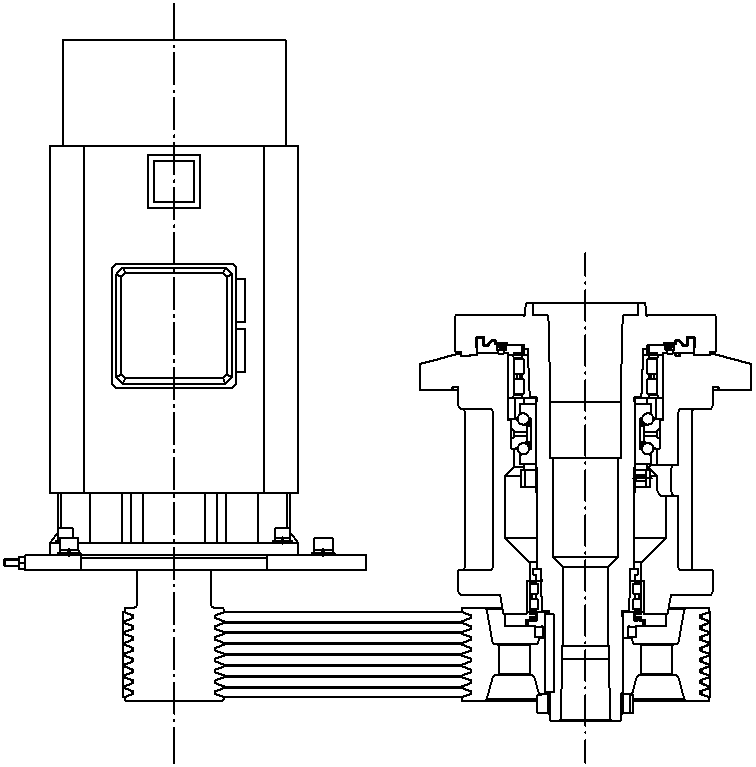

The spindle unit of this series of machine tools adopts the advanced and mature structure in the current international design. The front support of the main shaft is composed of a double row cylindrical roller bearing and a bi-directional thrust angular contact ball bearing, and the rear support is a double row cylindrical roller bearing; The bearing adopts imported precision spindle bearings, and the lubrication of the bearing adopts imported high-speed grease. The axial and radial preload of the spindle system can be adjusted with a nut, which has high radial and axial stiffness. The inner ring of the roller bearing can adjust the radial clearance, thereby achieving the best machining accuracy and lower working temperature.

The main motor of this series of machine tools drives the spindle to rotate through imported synchronous belts, ensuring high efficiency, low noise, and low vibration of the entire transmission system to meet the cutting requirements of various conditions such as low-speed high torque and high-speed high power of the machine tool. The spindle box and the base are integrated through holes, thereby giving the machine tool spindle assembly high rigidity.

The X/Z axis is driven by a servo motor and directly connected to a ball screw through an elastic coupling. The ball screw adopts a fixed installation method at both ends.

Both axis guide rails use Taiwanese cylindrical rolling guide pairs, which are of the four directional equal load type, with high precision, large load capacity, and fast roller movement speed. Its outstanding advantages are small size, high precision, low maintenance costs, and it is the preferred configuration for users who pursue high precision and cost-effectiveness. It is particularly suitable for occasions that require high consistency in part size.

This machine tool is a highly automated CNC machine tool, equipped with liquid

Pressure system. The main hydraulic control components of the hydraulic system are all selected from well-known sources

Brand or high-quality domestic products.

The machine tool adopts a domestically produced centralized automatic lubrication system and has liquid level and pressure alarm functions.

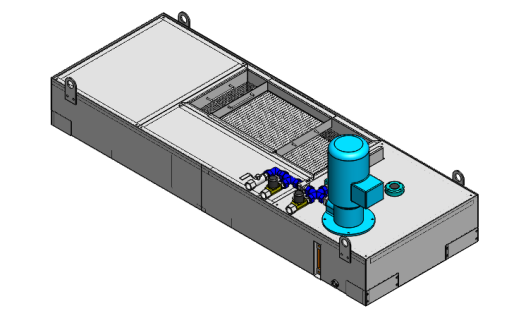

The cooling pump of this machine tool has a flow rate of 4m ³/h and a head of 40 meters. The cooling water tank is separated from the main engine to ensure that the accuracy of the machine tool is not negatively affected by cutting heat. Using a cooling pump, the water pipes on the base of the machine are connected to flush out the iron filings on the machine body, thereby reducing the impact of waste materials on the machine.

This machine tool is equipped with a drag chain chip conveyor, which is used to collect and transport various rolled, clustered, block shaped chips, as well as copper, aluminum, cast iron and other debris.

A : The conditions and period for the supplier to be responsible for quality: After the machine tool is accepted, it will enter the warranty period, which is twelve months. The equipment implements three guarantees and the warranty period is one year.

B : If the equipment fails during use, the supplier will respond within 2 hours after receiving the notice from the buyer and come up with a solution within 8 hours. If on-site processing is required, personnel will be assigned to the buyer within 48 hours to handle it.

C : If a failure occurs during the warranty period, the supplier will provide free repair services (except for damage to the machine tool caused by human factors by the buyer or the end user); the cost fee will be charged for failures caused by improper use.

D : After the machine tool arrives at the user's factory, if the installation and commissioning work cannot be carried out on time due to the buyer's reasons, the warranty period will expire 12 months after the arrival of the user, and the three guarantees service will no longer be provided.

E : Equipment accuracy standards are provided by the supplier with the contract.

| Machine parameters | |||

|---|---|---|---|

1.Equipment name |

CNC vertical lathe |

2. Model |

KD800 |

3. System |

FANUC 0i-TF |

||

Trip | |||

| x-axis | 450mm | z-axis | 500mm |

Capacity | |||

| Max.swing dia. | Φ950mm | Max.turning dia. | Φ850mm |

| Max.turing High | 500mm | ||

SPINDLE | |||

| Spindle Speed | 50-300rpm | Servo spindle motor | 22 |

| Dimension-Outside | Φ180mm | ||

Chuck &Automatic tool changer | |||

| Chuck type | Three jaw hydraulic chuck | Dia.Chuck | 32 inches |

| Work Station | Eight workstations+eight workstations | ||

ACCURACY | |||

| Repeat positioning | ±0.0012mm | Positioning | ±0.02mm |

| Least input increment | ±0.001mm | ||

POWER REQUIRE | |||

| Power Source | 3¢-AC 380V 50Hz±5% | Power Consumption | 35Kw |

| The machine tool has grounding protection and power-off protection | √ | Three color indicator light for machine tool working status | √ |

OTHERS | |||

| Cross weight | 12000kg | Floor space (length x width x height) | 3450*2550*3250mm |

The equipment adopts fully enclosed protection, and the protective device is safe and reliable, which should comply with the General Technical Regulations for Safety Protection of Metal Cutting Machine Tools GB15760-1995. | |||

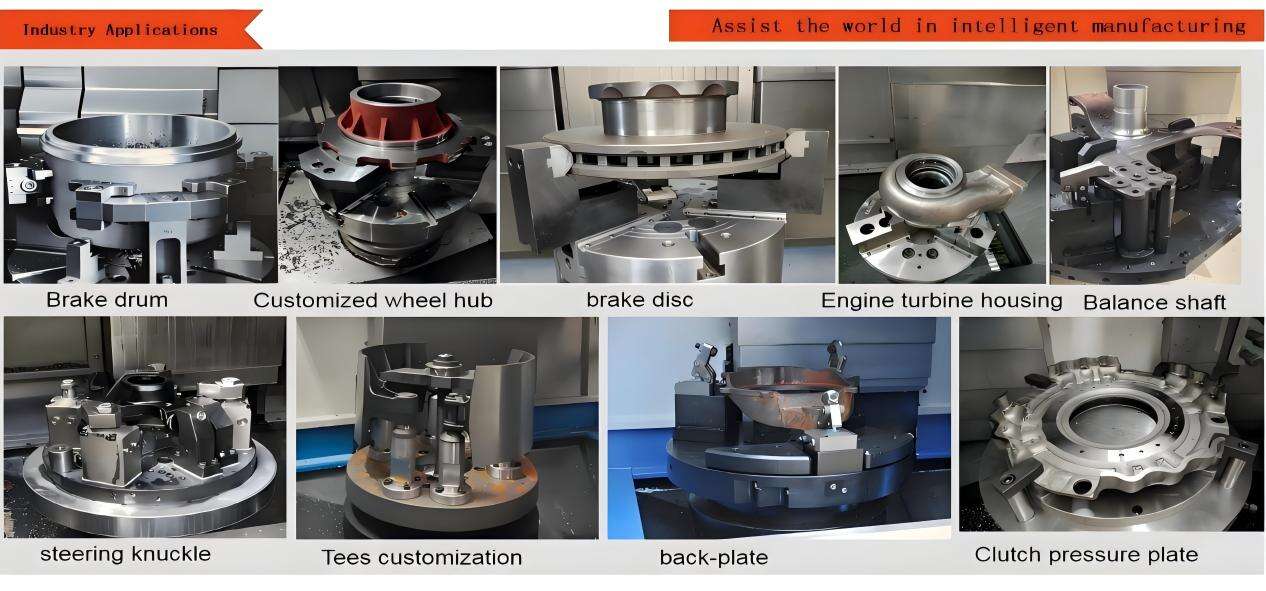

This machine tool is suitable for high-speed steel cutting tools, hard alloy cutting tools, and various high-performance cutting tools. It can process black metal, non-ferrous metal, and some non-metallic material workpieces. It can complete rough and fine machining processes such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, cutting grooves, steps, and circular arcs on the machine tool. Suitable for processing parts with large batch sizes, high machining accuracy, and high requirements for dimensional consistency.

Customer visit

Customer visit

Yes, we support ODM/OEM, and can design and customize exclusive models according to your needs.

A: Please tell me your specifications. We can choose the best model for you. You can also send us the product drawing. We will choose the most suitable machine for you.

A: 30% down payment after the contract, 70% payment before ship.ment, can be discussed according to your situation.

A: Our factory is located in Tengzhou City,Zaozhuang. China, zip code277500.Warmly welcome you to visit us.

The delivery time is 7-10 days. If you choose a special configuration, the delivery time will be correspondingly extended