A CNC machining center is an efficient automated machine tool composed of mechanical equipment and CNC systems, suitable for processing complex parts. CNC machining center is one of the most widely used and high-yielding CNC machine tools in the world.

A CNC machining center is an efficient automated machine tool composed of mechanical equipment and CNC systems, suitable for processing complex parts. CNC machining center is one of the most widely used and high-yielding CNC machine tools in the world. It has strong comprehensive processing capability, and can complete a large amount of processing content after one clamping of the workpiece, with high processing accuracy. For batch workpieces with moderate processing difficulty, its efficiency is 5-10 times that of ordinary equipment, especially it can complete many processing tasks that ordinary equipment cannot. It is more suitable for single piece processing or small batch multi variety production with complex shapes and high precision requirements. It integrates functions such as milling, boring, drilling, threading, and cutting threads into one device, enabling it to have multiple processing techniques. Machining centers are classified into horizontal and vertical machining centers based on the spatial position of the spindle during machining. Classified by process use, there are boring and milling machining centers and composite machining centers. Classified by special functions, there are single worktable, dual worktable, and multi worktable machining centers. Single axis, dual axis, three-axis, and replaceable spindle box machining centers. According to the classification of guide rails, there are: wire rail machining centers, hard rail machining centers, etc.

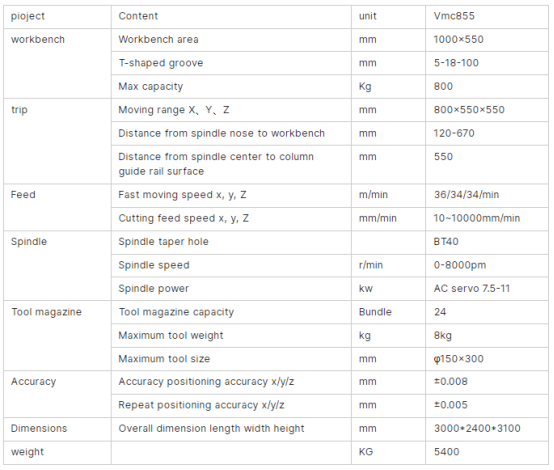

DETAIL DESCRIPTION

Control System

The control system is tailored to customer requirements Supported brands include GSK, Siemens, Fanuc, Syntec, and Mitsubishi.

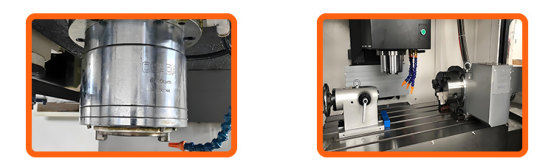

Taiwan Tool Magazine

The 24-tool arm type features a lightweight aluminum alloy tool disc, a Geneva wheel mechanism for smooth operation, linear bearings for low friction and durability.

Spindle

The machine is equipped with Taiwanese spindles from brands like ROYAL, KENTURN, OKADA, VOLIS, and AIMACH, offering high-speed high-precision performance, strong load capacity

Worktable

The worktable undergoes high-frequency quenching for enhanced rigidity, allowing for the integration of 4th and 5th axis rotary tables to process various parts and facilitate quick task switching

ADVANTAGE

High precision five axis machining

Support five axis linkage machining, capable of achieving high-precision machining of complex geometric shapes, meeting the requirements of high-precision industries.

Automated production capacity

It can be integrated with automation systems to improve production efficiency and reduce labor costs, in order to meet the needs of modern intelligent manufacturing.

Adaptable process integration

Vertical machining centers support the integration of multiple machining processes, such as cutting, milling, surface treatment,etc., to meet diverse customer needs.

Optimized security protection design

The design takes into account the safety needs of users and is equipped with multiple safety protection devices to ensure the safety of operators during the processing

Efficient cutting and improving efficiency

The vertical machining center, combined with high-speed spindle and high torque power system, provides excellent cutting performance and greatly improves production efficiency.

Real time monitoring and data analysis

Equipped with advanced data monitoring system, real-time tracking of processing process, analysis of production data to optimize processing parameters

High rigidity machine tool structure

The machine tool adopts high rigidity materials and precision casting technology, which enhances the stability of the entire structure and ensures that deformation will not occur during high load processing

Multi functional tool system

Built-in intelligent tool monitoring system, automatically selects the best tool according to processing requirements, improves tool utilization, and reduces production costs.

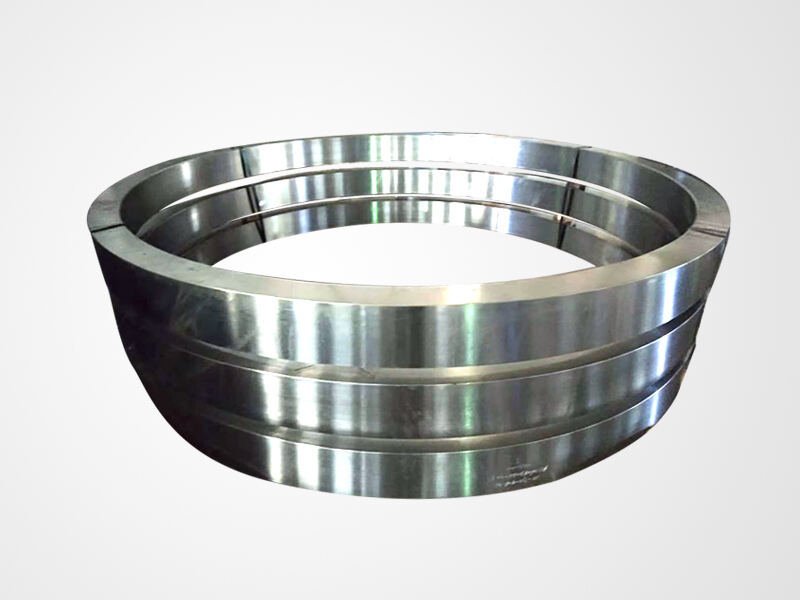

In the field of mechanical manufacturing, CNC machining centers are widely used to manufacture various mechanical equipment and components. For example, used for machining tools such as machine tools, molds, fixtures, gears, etc. In the aerospace industry, CNC machining centers play an important role in processing aircraft components such as engine rotors and flight control systems.In the field of mechanical manufacturing, CNC machining centers are widely used to manufacture various mechanical equipment and components. For example, used for machining tools such as machine tools, molds, fixtures, gears, etc. In the aerospace industry, CNC machining centers play an important role in processing aircraft components such as engine rotors and flight control systems.

Taiyun (Shandong) CNC Machine Tool Co., Ltd., a 26-year-old source manufacturer, has an independent factory area of over 60,000 square meters in Tengzhou Economic Development Zone and more than 130 employees. The company quantitatively manages and performance-assesses product quality, focuses on every process detail, adopts a bidding mechanism for supply customers to ensure strong cooperation and international quality of supporting components. It emphasizes investment in scientific and technological R & D, owns an enterprise technology R & D center and a cohesive, combat-effective and innovative management and R & D team. The company's products have been exported to Yunnan, South Korea, Thailand, Russia and other regions, receiving favorable feedback from customers.

After years of development, Taiyun (Shandong) CNC Machine Tool Co., Ltd. has successfully established a wide and stable customer network, and maintained deep cooperation with many industry-leading enterprises such as China National Heavy Duty Truck Group and China National Automotive Group.

1.Can you provide design customization service?

Yes, we support ODM/OEM, and can design and customize exclusive models according to your needs.

2.How to choose the most suitable machine?

A: Please tell me your specifications. We can choose the best model for you. You can also send us the product drawing. We will choose the most suitable machine for you.

3.What are your payment terms?

A: 30% down payment after the contract, 70% payment before ship.ment, can be discussed according to your situation.

4.Where is our factory located?

A: Our factory is located in Tengzhou City,Zaozhuang. China, zip code277500.Warmly welcome you to visit us.

5. What is your delivery time?

The delivery time is 7-10 days. If you choose a special configuration, the delivery time will be correspondingly extended